Simpler and More Efficient Than Any Other Turbo Design on the Market

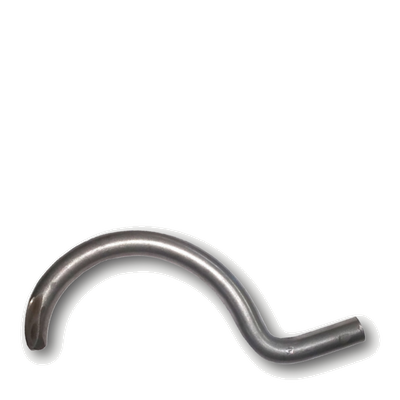

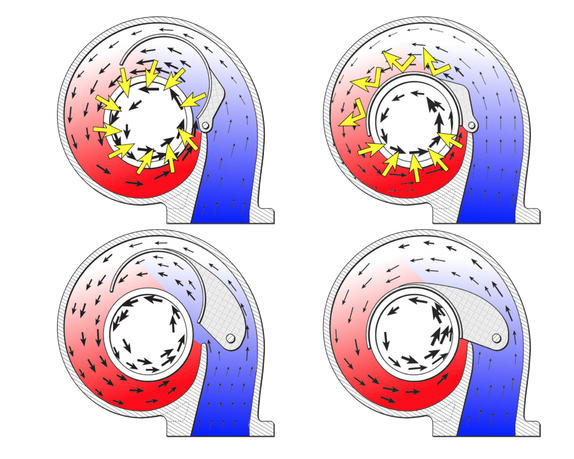

The vane in the Switchblade makes it take off like a small A/R turbine housing and then opens at a preset boost pressure, making it perform like a big turbine housing. Giving you the best of both worlds, quick spool-up on takeoff and great power on the top end.

The vane used to enhance performance in the Switchblade Turbo

Variable Geometry Turbo parts found in various Holset and Cummins Turbos

Variable Geometry Turbo parts found in Honeywell Models, like the Detroit Series 60

On takeoff, the vane is closed, pinching the exhaust flow down to the smaller end of the turbine housing scroll before it can impact the turbine wheel with more force at lower engine rpm’s. Using the vane lets us use a larger turbine housing than a conventional turbo would need to get low-end performance and then open up the vane to get better top-end performance with the bigger turbine housing.

When boost pressure hits a predetermined level, the vane actuator starts opening the vane and allows more and more exhaust gas access thru the volute slot to impact more of the turbine wheel circumference. The vane opening decreases the exhaust back pressure letting the engine to take advantage of the larger turbine housing and breathe more efficiently.

The Switchblade Turbo is a very simple design performing like two turbo’s in one, with NO nozzle vanes to change to suit different driving styles, and vane operation is automatically self-controlled.

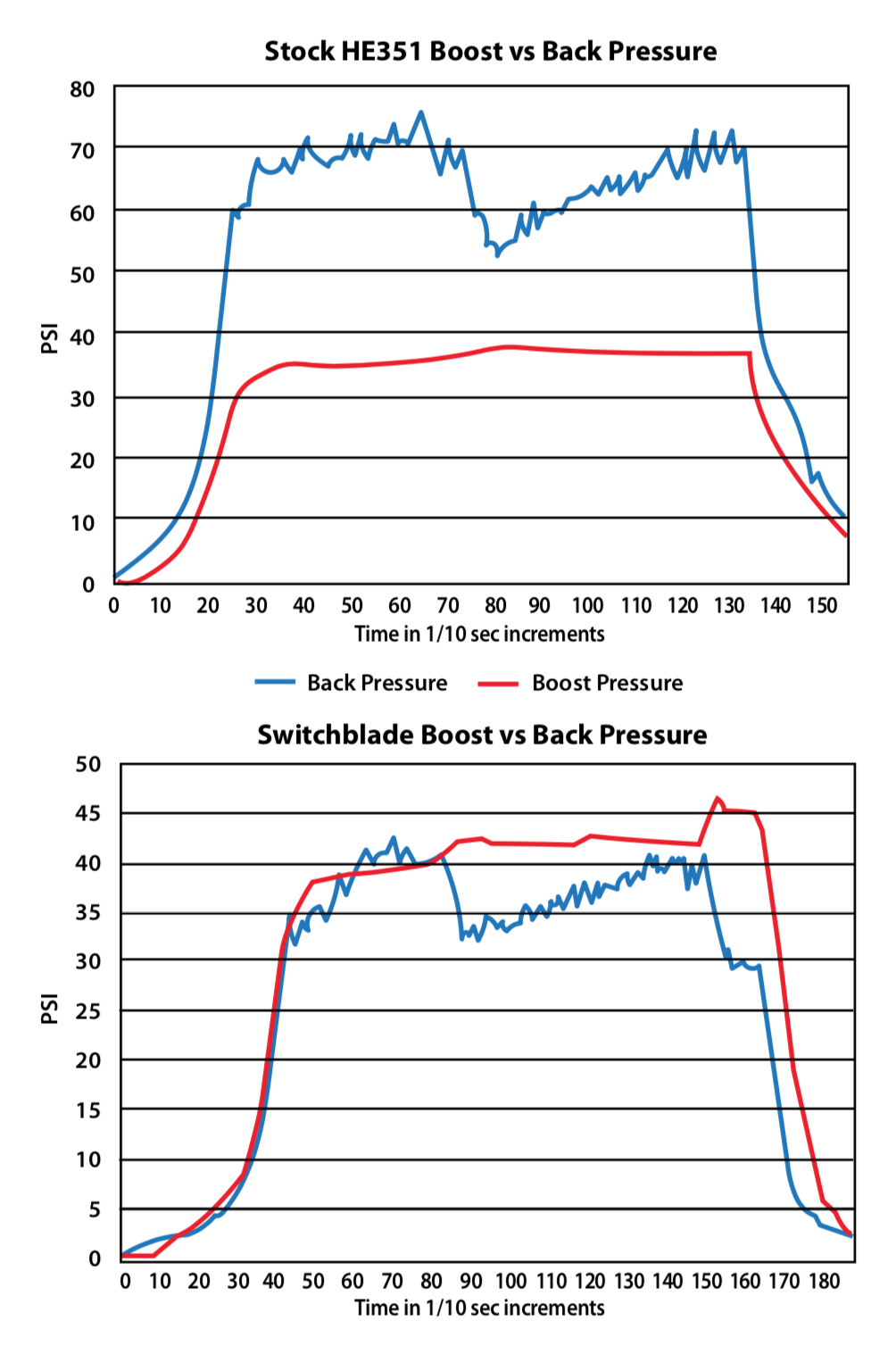

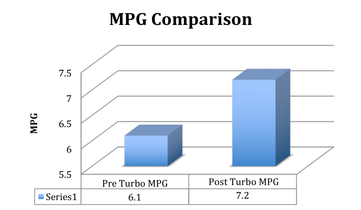

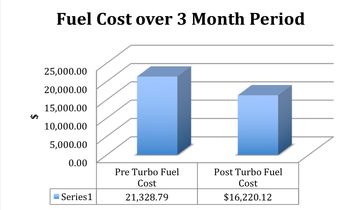

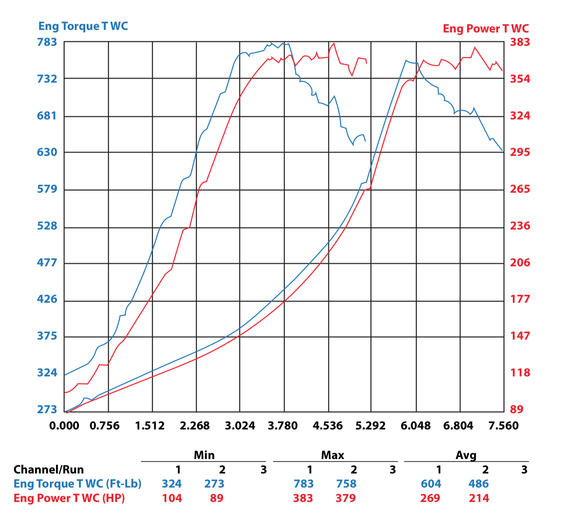

Power & Performance Results

The horsepower and torque lines on the right side of the graph are an S363 turbo without the Switchblade vane. The horsepower and torque lines on the left side of the graph are the same turbo as the Switchblade vane.

All other factors, such as fuel and tuning, were untouched, with the vane being the only variable.

The graphs below illustrate the Switchblade's impact on the performance of the turbo. There is a traditional trade-off between quick spool-up times and top-end performance. A smaller housing enables the turbo to generate boost more quickly; however, creates engine back pressure under towing or heavy use conditions. The Switchblade uses a significantly larger turbo than the stock configuration and is able to spool up quicker due to the directed flow over the turbine tips. Note the difference in back pressure and boost pressure between the Switchblade and the stock with similar spool-up times. This reflects the turbo’s ability to respond quickly from low flow conditions while still providing superior performance under heavy use conditions.